CONTACT US

Laiwu Yida Materials Technology Co., Ltd.

ADD:No. 191 Wudangshan Road, Laiwu High-tech Zone, Shandong Province

電話:0531-76251099

手機:0531-76251091

Email:lwxylc@163.com

Web:www.qddongshuo.cn

Differences between Activated Alumina and Molecular Sieves

Molecular sieves have strong hygroscopicity and should be used for purification of gases. When preserved, direct exposure to air should be avoided. Molecular sieves with long storage time and moisture absorption should be regenerated before use. Molecular sieves avoid oil and liquid water. Avoid contact with oil and liquid water when using.

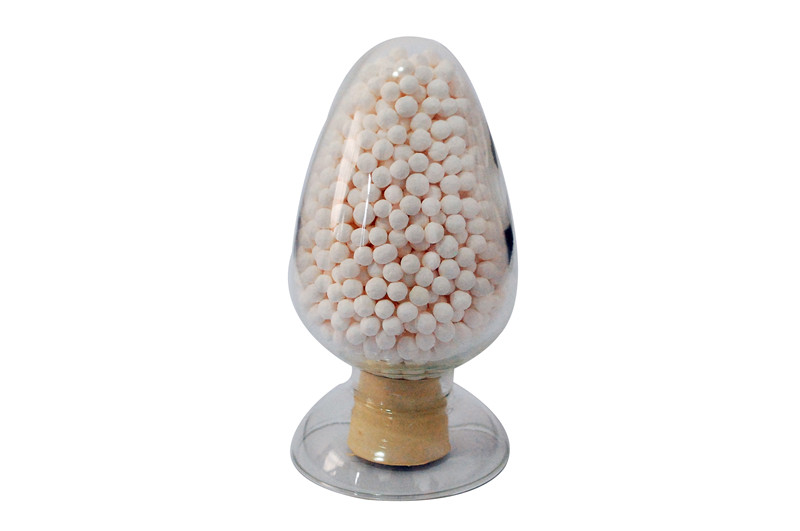

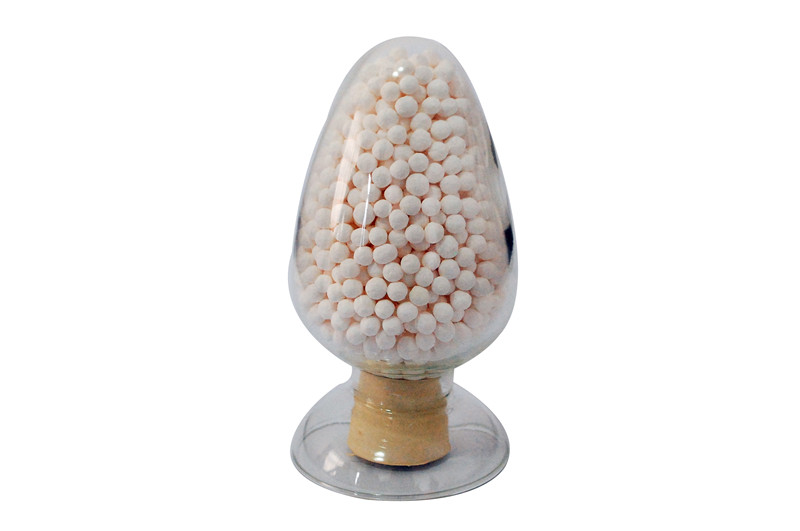

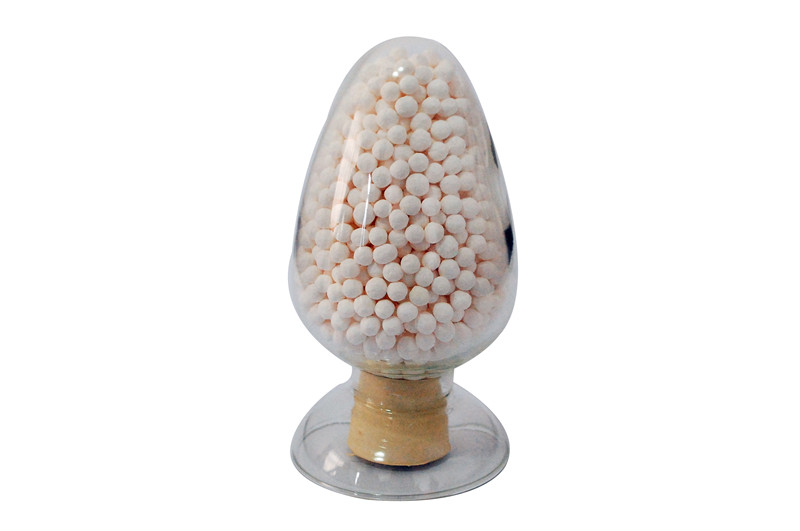

Activated alumina balls are mainly used for dehydration and drying of industrial gases, such as air, oxygen, nitrogen, smelting gas and petroleum cracking gas. Activated alumina produced by our company is an X-P type alumina product with many fine holes and high strength. It has strong affinity for water and is a desiccant for deep drying of trace water. It has the characteristics of water immersion in use medium, no softening, no expansion, no pulverization, liquid phase drying, textile industry, oxygen industry and automatic instrument air drying.

There is no difference between zeolite and activated alumina, but there is a difference in fact. The static water balance adsorption of 13X zeolite can reach about 23%. Activated alumina in 17% sample. In addition, 13X molecular sieve can remove more than 10 A molecules because of its micropore diameter of 10 A. The selectivity is high. Activated alumina is usually pre-treated at the lower part of the purifier.